Prototyping at the Speed of Ideas: Rapid Manufacturing is Redefining Product Development

In the race to bring new products to market, the winners aren’t just faster—they’re smarter.

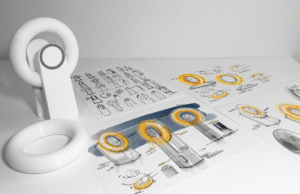

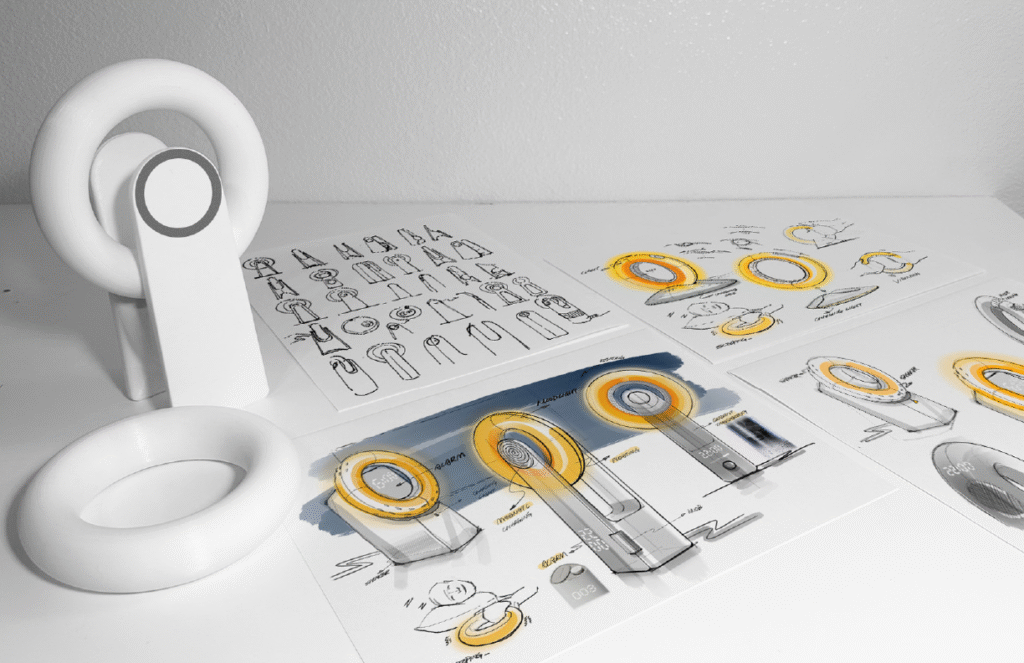

Over the last decade, rapid prototyping has evolved from a niche capability to a strategic cornerstone for engineering teams worldwide. The ability to create, test, and refine physical models in days rather than months has fundamentally changed the economics—and the risks—of innovation.

At the center of this shift is an increasingly sophisticated toolkit of technologies: 3D printing, CNC machining, rapid injection molding, and sheet metal fabrication. Together, they offer design and manufacturing teams an unprecedented ability to iterate quickly, solve problems early, and move to production with greater confidence than ever before.

But the real advantage isn’t just in the machines. It’s in how smart companies use them.

A New Era for Product Innovation

Traditionally, product development followed a slower, riskier path: long design cycles, expensive tooling investments, and limited opportunities to adjust once manufacturing began. A mistake uncovered late in the process could cost millions—and months of recovery time.

Today, rapid prototyping flips that equation. Using digital manufacturing workflows, engineers can test form, fit, and function early and often. Minor changes that once required weeks of retooling and retesting can now be made in hours. Iteration becomes a feature of development, not a crisis response.

The results are clear:

- Faster product launches

- Lower upfront costs

- Higher quality outcomes

- Greater market adaptability

How Rapid Prototyping Works: Tools of the New Trade

Additive Manufacturing (3D Printing) leads the charge, offering options like SLA for high-detail cosmetic models, SLS and MJF for durable functional parts, DMLS for real metal components, and FDM for fast, low-cost conceptual models.

Meanwhile, CNC Machining holds the line for projects demanding tight tolerances, true material properties, and functional mechanical performance under stress.

On the forming side, Rapid Injection Molding with aluminum tools provides a critical bridge between prototyping and full production, delivering true molded parts without the traditional six-figure investment in steel tooling. Sheet Metal Fabrication enables fast production of brackets, housings, and enclosures critical for industrial and commercial applications.

The shared DNA across these technologies is simple: speed, flexibility, and risk reduction.

Strategic Advantages Beyond Speed

The benefits of rapid prototyping extend beyond just getting a part faster.

Cost Reduction: By removing the need for custom tooling early in the design phase, teams save substantial capital and reduce the sunk costs associated with bad designs.

Real Collaboration: A CAD file may look impressive on a screen, but a physical prototype drives real conversations. Engineers, marketers, and decision-makers can engage with tangible products, identify flaws, and converge on better solutions faster.

Functional Confidence: Early testing in real-world conditions—whether for mechanical load, chemical resistance, or assembly fit—means that final products are validated, not guessed at.

Customization at Scale: Digital workflows make it practical to test multiple design variations in parallel, offering market-specific or user-specific products without blowing up development budgets.

Key Considerations: Not Just Fast, but Smart

Rapid prototyping works best when it’s strategic.

Material selection, process choice, and manufacturing foresight all play critical roles in maximizing the value of early-stage prototypes.

- Material Alignment: Match prototype materials to the testing need. SLA for looks, SLS or CNC for load-bearing tests, rapid molding for production validation.

- Process Planning: Early ideation? Go fast with SLA or FDM. Functional validation? Use SLS, MJF, or CNC. Pre-production ramp? Rapid molding is your move.

- Design for Manufacturability (DFM): Always design prototypes with production in mind. Features like wall thickness, draft angles, and assembly-friendly geometry should be baked in from the start, not bolted on later.

A prototype that’s easy to print but impossible to mold isn’t saving you time—it’s wasting it.

From Prototype to Production: Building the Bridge

Transitioning from prototyping to production is a discipline in itself. The best teams understand that every prototype cycle is a rehearsal for full-scale manufacturing.

Critical steps include:

- Geometric Consistency: Ensuring design features align with real-world manufacturing methods.

- Material Validation: Testing final or equivalent materials early in the process.

- Iterative Refinement: Running multiple prototype cycles to fine-tune assembly, usability, and manufacturability.

Done right, this approach doesn’t just smooth the path to production—it accelerates it.

The Future is Iterative

Rapid prototyping isn’t a side tool anymore. It’s the main engine behind agile product development.

Companies that embrace fast, frequent, intelligent iteration are outpacing those stuck in slower, more rigid models.

Speed matters.

But speed without strategic execution is just chaos.

Smart prototyping brings both—and that’s where real innovation lives.

For expert consultation on rapid prototyping, manufacturing strategy, and bringing your next innovation to market faster and smarter, contact RapidMade at rapidmade.com or email info@rapidmade.com.